In October of golden autumn, Foshan Baiyang Feed Co., LTD. (Fujian Branch), which was contracted by Honghuan Machinery, "renovated and expanded two sets of 5-ton shrimp granulation lines", passed debugging and successfully put into production at one time, and was highly recognized by Foshan Baiyang. The success of this project is not only the comprehensive strength of Honghuan Machinery construction aquatic products project, but also a comprehensive reflection of the whole process management of Honghuan engineering project "442".

40% discuss cooperation and design

Collaboration and Design

In the first half of this year, Foshan Baiyang due to business development needs, to expand 2 shrimp feed lines on the basis of the original plant, the whole project involves the original production workshop more than 70% of the feed production process, equipment and plant structure for a full range of transformation and upgrading, and only 60 days of construction period. In the process of bidding, in the face of multiple strict screening by Foshan Baiyang, Honghuan Machinery stood out in the competition of many peers with rich industry experience and professional design and implementation capabilities.

To ensure the smooth and effective implementation of the project. After the contract was signed, the marketing, technology, engineering project managers and other relevant personnel of Honghuan Company went to Baiyang Company for many times to fully understand, communicate, adjust and confirm the content that could not be realized in reality in the process flow and equipment layout during the bidding. The two sides reached an agreement to adjust and add content, laying a solid foundation for the subsequent smooth construction.

40% of the projects implemented Collaboration and Design

In the construction phase, Honghuan based on the principle of "completion on time, customer satisfaction", according to the actual situation of the site, formulated a detailed site construction plan, according to the construction plan, formulated a detailed delivery demand plan, and tracked the actual progress and completion of each department every week through ERP.

Although there has been sufficient communication and confirmation in the early stage, the complexity of the actual production environment still leads to the emergence of new problems. Faced with these situations:

Honghuan's experienced project managers always carefully check and analyze the actual situation on the site, and give feedback to the company's professional and technical personnel in the first time. The technical personnel go to the site for confirmation, coordinate with Baiyang company to discuss and confirm the effective plan and adjust it in the first time, and quickly feedback the production and procurement of Honghuan company to all departments for adjustment and implementation.

At the same time, with many years of rich installation experience, the project manager discussed and confirmed with the installation and implementation personnel every day, gave full play to their own experience advantages and flexibility, and effectively adjusted according to the actual conditions of the construction site.

It is through the internal and external collaborative management of the company that Honghuan maximizes the smooth implementation process of the project, so as to ensure the smooth progress of the overall process of the project, and always thinks that the customer creates the greatest value as the first responsibility.

20% Project delivery

Collaboration and Design

The smooth construction process brings great confidence to the project delivery. During the completion and commissioning period, Honghuan takes "ensuring the normal and stable operation of equipment and effectively achieving the production capacity target" as the first task.

Pay attention to the actual running of the device, and report the same day to handle the exception.

Track the production efficiency of the equipment every day, evaluate the production capacity data of the equipment in actual operation, and adjust the optimization.

Track the degree of automation to verify that the automated operation of the equipment is smooth and efficient.

Verify the cleaning effect of the zero emission system to check whether the environmental protection measures in the production process are up to standard and whether they meet the requirements of cleaner production.

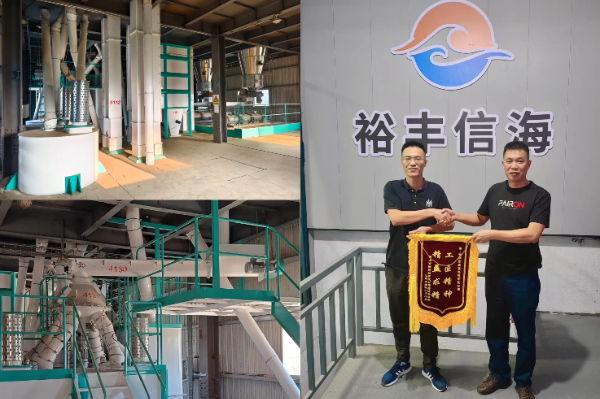

It is based on the concept of the whole process management of the in-depth practice project "442" that the complete expansion project of Foshan Baiyang shrimp granulation line was successfully debugging at one time. After comprehensive testing, whether it is product quality, production efficiency or other related indicators, the production indicators have reached the expected effect of Foshan Baiyang, are perfectly in line with customer requirements. In particular, the project has achieved significant environmental success with the successful introduction of an advanced zero-emission system, which not only reduces the environmental impact, but also improves the cleanliness of the production process. In addition, the clean feed technology used in the project further ensures the high quality and safety of feed products, meeting the growing market demand for environmentally friendly and healthy farming.

Honghuan will rely on the strategic goal of "one-time delivery of engineering projects", adhere to the concept of engineering project 442 whole process management with rigorous and practical work style, forge ahead, constantly improve its comprehensive strength, create more value for customers, and join hands with more partners to move towards a better tomorrow.